The phone call always follows the same pattern. A customer has been told their cable isn't certified correctly. The project is on hold. The inspector won't sign off. Now they're scrambling to find replacement product that meets requirements they don't fully understand. By the time they reach your counter, they're frustrated, behind schedule, and looking to you for answers.

At Distributor Wire & Cable, we see this scenario play out regularly. The confusion is understandable. Cable certifications involve overlapping standards from multiple organizations, each with their own marks, requirements, and jurisdictions. A cable might be NEC compliant but lack UL listing. It could be CSA certified for Canada but not ETL listed for the United States. The combinations and requirements multiply quickly, and the consequences of getting it wrong are real.

This guide cuts through the confusion. We'll explain what each major certification means, how they relate to each other, when specific certifications are required, and how to verify that cable actually meets the specifications claimed on its jacket. Whether you're helping a contractor meet code requirements or sourcing product for your own operations, understanding cable certifications protects everyone in the supply chain.

What Cable Certifications Actually Mean

A cable certification is formal confirmation from a recognized standards body or testing organization that a product meets defined safety, performance, or environmental requirements. The cable manufacturer submits their product for testing, and if it passes, they earn the right to mark their cable with the certifying organization's symbol.

But that mark on the cable jacket represents far more than passing a one-time test. It means the cable was manufactured using materials that meet specifications. That it underwent flame testing, insulation resistance testing, voltage testing, and whatever other evaluations the standard requires. That the manufacturing facility agreed to periodic inspections to verify continued compliance. And that the manufacturer is willing to stake their business on that cable performing as specified.

For distributors and contractors, certifications serve three critical functions. First, they provide assurance that the cable is safe to install and will perform reliably in its intended application. Second, they satisfy code requirements and pass inspection. Third, they establish clear liability—when something goes wrong, properly certified cable with documented test results protects everyone in the chain from manufacturer to installer.

The complexity comes from the fact that different certifications address different concerns. Some focus on electrical safety. Others address fire performance. Still others deal with environmental impact. A complete understanding requires knowing what each certification covers and how they work together.

The National Electrical Code: The Foundation of Cable Requirements

The NEC isn't a certification mark you'll find printed on cable. It's the foundation on which most other certifications are built. Published by the National Fire Protection Association and updated every three years, the NEC provides the comprehensive set of requirements for safe electrical installations in the United States. Virtually every municipality adopts some version of the NEC as their local electrical code, making it the de facto standard nationwide.

The NEC approaches cable requirements systematically through numbered articles. Article 310 covers conductors for general wiring—everything from individual THHN wire to multi-conductor cables operating below 2,000 volts. Article 311 addresses conductors above 2,000 volts. Articles 320 through 340 define specific cable types: Type NM (nonmetallic-sheathed cable), Type MC (metal-clad cable), Type AC (armored cable), and dozens more. Each cable type has specific construction requirements, permitted uses, and installation methods specified in its respective article.

National Electrical Code (NEC)

The NEC sets the baseline for safe electrical installations in the United States. Updated every three years, it outlines how cables must perform to be code-compliant.

NEC-compliant cables are tested for:

Fire resistance and flame spread

Temperature and current-carrying capacity

Voltage insulation and environmental suitability

Compatibility with approved installation methods

Take Type THHN/THWN-2 building wire as an example. The NEC specifies that this conductor must have thermoplastic insulation rated for high heat (THHN) and be suitable for wet locations (THWN). The "-2" indicates it can operate continuously at 90°C. The wire must meet flame resistance requirements. It needs specific insulation thickness based on voltage rating. And it can only be installed in approved locations using approved methods.

The NEC compliance isn't self-certified—manufacturers work with third-party testing laboratories to verify their cables meet NEC requirements. This is where organizations like UL, ETL, and CSA enter the picture. These independent laboratories test cables against NEC specifications and issue listings when products pass. When you see UL listed Type THHN wire, that UL listing confirms the wire meets all NEC requirements for that cable type.

For type: entry-hyperlink id: 5WhYDi5H7kXAIXvUawvjLN covered by NEC Article 336, the requirements become more specific. Type TC cable must pass flame testing appropriate for its installation method. It needs oil resistance for industrial environments. The jacket must protect against physical damage. And for cables carrying both power and data—increasingly common with Power over Ethernet deployments—the NEC includes specific ampacity tables to prevent overheating when cables are bundled in trays.

Understanding the NEC structure helps you match cable specifications to project requirements. When a customer asks for "code compliant" cable, they're really asking for cable that meets the NEC requirements for their specific application. That might be Type NM-B for residential wiring, Type MC for commercial installations, or Type USE for underground service entrance applications. Each has different NEC requirements, and the certifications on the cable must confirm it meets those requirements.

UL Certification: The Gold Standard for Safety Testing

When most people talk about certified cable, they're referring to UL certification. Underwriters Laboratories has been testing electrical products for safety since 1894, and the UL mark has become synonymous with product safety in North America. But UL certification isn't monolithic—it comes in several forms, each serving a different purpose in the electrical supply chain.

UL Listed products have been tested for safety as complete, finished products intended for end-use installation. When you see a UL Listed mark on cable, that cable has undergone comprehensive safety testing relevant to its intended application. The testing evaluates insulation integrity, flame resistance, voltage ratings, temperature performance, and resistance to environmental hazards like moisture and chemicals. UL doesn't just test a sample and walk away—listing requires ongoing factory inspections to ensure continued compliance. This follow-up service program means every foot of UL Listed cable rolling off the production line maintains the same quality standards that earned the initial listing.

Underwriters Laboratories (UL)

UL is an independent testing organization that evaluates electrical products for safety. UL certification confirms a cable has passed rigorous lab tests and ongoing quality audits.

Distributors can trust UL cables for:

Reliable fire and smoke performance

Consistent electrical performance under load and temperature changes

Durability under stress and environmental exposure

Resistance to chemicals and degradation

UL Recognized components serve a different role. These are materials and components intended for incorporation into finished products. Think appliance wiring material (AWM) used inside equipment, or cable that will be assembled into a larger listed system. UL Recognized components undergo testing, but with the understanding that they'll be used in controlled applications by manufacturers or qualified installers. You might see UL Recognized wire in control panel fabrication or inside listed equipment, but not in general building wiring applications.

The distinction matters when you're sourcing cable. If a customer needs cable for permanent building installation—the type covered by NEC articles for general wiring—they need UL Listed cable, not UL Recognized components. If they're building equipment or control panels where the cable will be enclosed and protected, UL Recognized AWM might be appropriate and more cost-effective.

UL testing for cable is remarkably thorough. For a typical building wire to earn UL listing, it undergoes flame tests to verify it won't propagate fire. Insulation gets subjected to voltage stress far exceeding its rated voltage to ensure dielectric strength. The cable is exposed to temperature extremes, checking that insulation doesn't crack when cold or melt when hot. If the cable claims oil resistance, it gets soaked in oil to verify the jacket doesn't degrade. For cables rated for sunlight resistance, UV exposure testing confirms the jacket won't break down under outdoor conditions.

The UL Wire and Cable Marking Guide provides detailed information about what each designation means and what testing the cable has passed. When you see marks like "VW-1" on cable, that indicates vertical wire flame testing per UL 1581. A "CMP" mark means plenum cable tested for use in air-handling spaces with stringent flame and smoke requirements. These aren't marketing terms—they're specific test protocols with defined pass/fail criteria.

For distributors helping customers specify cable, understanding UL test protocols helps match cable to application. A contractor installing cable in a factory with significant oil exposure needs cable with oil-resistant jacket that passed UL testing for chemical resistance. Data center installations where cables run through plenum spaces require CMP rated cable that passed both flame tests and smoke generation tests. These aren't interchangeable, and the UL listing confirms the cable actually meets the application requirements.

ETL and CSA: Nationally Recognized Alternatives to UL

Here's something that confuses many people in the electrical industry: UL isn't the only game in town. Several other organizations operate as Nationally Recognized Testing Laboratories (NRTLs) under the Occupational Safety and Health Administration's certification program. The two most prominent alternatives are Intertek's ETL certification and the Canadian Standards Association (CSA) certification.

Here's the critical point: for regulatory purposes, ETL Listed and UL Listed are equivalent. Both test to the same standards—often the exact same UL standards that define safety requirements for electrical products. Both conduct ongoing factory inspections. Both are NRTL-approved by OSHA. An electrical inspector treating ETL Listed cable differently from UL Listed cable would be incorrect. The National Electrical Code recognizes products listed by any qualified NRTL, not just UL.

The practical difference comes down to testing organization, cost, and timeline. Some manufacturers prefer working with ETL because of faster turnaround times or more responsive service. Others stick with UL because of brand recognition and global acceptance. For the distributor or contractor installing the cable, the listing should perform identically because they test to identical standards.

CSA certification holds particular importance for products sold in Canada. While CSA is also an NRTL and can certify products for the U.S. market, its primary role is certifying products meet Canadian Electrical Code requirements. You'll often see combination marks—cULus indicates a product meets both U.S. and Canadian requirements through UL testing, while cCSAus means the same through CSA testing. These dual certifications streamline the approval process for manufacturers serving both markets.

For products marked with just "ETL Listed" or "UL Listed" without the "c" prefix, those certifications apply to U.S. installations. If your customer is working on a Canadian project, verify the cable carries the appropriate Canadian certification. The same physical cable might need different testing and certification to meet Canadian requirements, particularly around flame performance standards which differ slightly between the CEC and NEC.

The practical takeaway: when sourcing cable for a project, verify it carries an NRTL listing from UL, ETL, CSA, or another OSHA-recognized laboratory. The specific laboratory matters less than confirming the cable actually carries legitimate listing for the jurisdiction where it will be installed. And if someone tells you ETL Listed cable is somehow inferior to UL Listed cable, they're misinformed. The testing standards are identical, and inspectors treat them equally.

RoHS Compliance: Environmental Standards Matter Too

While NEC and UL certifications focus on safety and performance, RoHS compliance addresses an entirely different concern: the environmental and health impacts of hazardous substances in electrical and electronic equipment. RoHS stands for Restriction of Hazardous Substances, and it originated as a European Union directive that has since been adopted in various forms by jurisdictions worldwide, including several U.S. states.

The original RoHS directive restricted six hazardous substances: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). Later amendments added four phthalates commonly used as plasticizers: DEHP, BBP, DBP, and DIBP. These substances can pose risks to human health during manufacturing, installation, use, and particularly during disposal when electrical equipment reaches end-of-life.

RoHS (Restriction of Hazardous Substances)

RoHS focuses on environmental safety by limiting hazardous materials in electrical products. Developed in the EU, RoHS standards are now widely adopted across U.S. supply chains.

RoHS-compliant cables are manufactured without:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent chromium (Cr⁶⁺)

Certain flame retardants (PBB, PBDE)

For cable, RoHS compliance primarily affects insulation and jacket formulations. Traditional PVC compounds often contained lead as a stabilizer and various brominated flame retardants. RoHS-compliant cables substitute safer alternatives—calcium-zinc stabilizers instead of lead, and non-brominated flame retardants. The maximum allowed concentration is 0.1% by weight for most restricted substances, with stricter 0.01% limits for cadmium.

The practical impact on cable selection depends on the application and jurisdiction. In the European Union, RoHS compliance is mandatory for electrical and electronic equipment. U.S. federal regulations don't mandate RoHS compliance broadly, but several states—including California, Illinois, Minnesota, and New York—have enacted RoHS-style restrictions for certain products. More significantly, many large customers specify RoHS-compliant cable as part of corporate environmental policies, regardless of legal requirements.

For specialty cable applications like data center infrastructure or renewable energy systems, RoHS compliance often becomes a procurement requirement even when not legally mandated. Organizations pursuing LEED certification or other green building standards typically specify RoHS-compliant materials throughout their projects. This makes RoHS compliance increasingly important for distributors to track, even on products where it's not technically required by code.

Verifying RoHS compliance requires proper documentation. RoHS-compliant products in Europe must carry the CE mark, which indicates conformity with all applicable EU directives including RoHS. Manufacturers should provide declarations of conformity and technical documentation showing material composition and test results. For distributors, maintaining this documentation protects you if questions arise about product compliance during or after installation.

The confusion around RoHS often comes from the fact that it's not an electrical safety standard and isn't enforced by electrical inspectors. A cable can be fully NEC compliant and UL listed while not being RoHS compliant. Conversely, RoHS-compliant cable might not carry the electrical certifications needed for legal installation. These are parallel requirements serving different purposes, and both matter for comprehensive compliance.

NFPA Standards: Fire Performance Beyond the NEC

The National Fire Protection Association doesn't just publish the NEC. They maintain a comprehensive library of standards addressing fire safety in specific applications and environments. Several NFPA standards directly impact cable selection, particularly for installations where fire performance is critical.

NFPA 70, the National Electrical Code, sets baseline requirements for cable flame resistance and smoke generation. But NFPA 262 goes further, establishing the test method for evaluating flame propagation height on electrical cables installed in cable trays. This is the test that determines whether a cable can be marked as CMR (Communications Riser) or CMP (Communications Plenum). The test exposes cables to flame in a controlled environment and measures how far the flame travels up the cable sample. Cables that limit flame spread to defined parameters pass the test and earn the appropriate rating.

NFPA 72, the National Fire Alarm and Signaling Code, establishes requirements for fire alarm system wiring. Fire alarm cable must meet specific performance criteria because these systems must continue functioning during a fire to provide warning and support evacuation. Cable marked FPLR (Fire Power Limited Riser) or FPLP (Fire Power Limited Plenum) has been tested to verify it can maintain circuit integrity under fire conditions. For mission-critical circuits, cable with CI (Circuit Integrity) ratings undergoes even more severe testing to demonstrate continued operation during fire exposure.

For cables installed in specialized environments, other NFPA standards come into play. NFPA 79 covers industrial machinery and establishes requirements for machine tool wiring. NFPA 99 addresses healthcare facilities and their unique safety requirements. NFPA 110 covers emergency power systems and their associated wiring. Each standard includes specific cable requirements relevant to its application area.

The practical significance for distributors is recognizing that "code compliant" isn't a simple yes-or-no question. A cable that meets NFPA 70 requirements for general building wiring might not meet NFPA 262 requirements for a cable tray installation. Fire alarm cable needs NFPA 72 compliance. Healthcare facilities might require cable meeting NFPA 99. Understanding which NFPA standards apply to a specific project ensures you're quoting cable that will actually pass inspection.

How Different Certifications Work Together

The real-world complexity of cable certification comes from understanding how multiple standards and certifications interact. A single cable might need to satisfy NEC requirements, carry UL listing, meet NFPA flame test standards, and demonstrate RoHS compliance. These aren't alternatives—they're complementary requirements that all must be met simultaneously for many applications.

Consider a typical Type TC tray cable installation in an industrial facility. The NEC Article 336 defines construction requirements for Type TC cable—conductor sizes, insulation types, permitted jacket materials, and installation methods. The cable must carry listing from an NRTL like UL or ETL confirming it meets those NEC construction requirements. If the cable runs through cable tray, it needs to pass NFPA 262 flame testing. If the facility exports to Europe or follows corporate environmental policies, the cable might need RoHS compliance. And if it's installed in a wet environment with chemical exposure, the jacket must be rated for those specific conditions.

Each certification confirms a different aspect of the cable's suitability. The NEC compliance verifies basic electrical safety and construction. The UL listing provides independent confirmation that the cable meets NEC requirements. The NFPA 262 testing confirms fire performance in the specific installation method. The RoHS compliance addresses environmental concerns. None of these replace the others—they work together to provide comprehensive assurance.

For structured cabling in commercial buildings, the certification requirements stack even higher. The cable must meet TIA/EIA performance standards for Category 5e, 6, or 6A. It needs NEC compliance under Article 800 for communications circuits. The flame rating must match the installation method—CMP for plenum, CMR for riser, or CMG for general use. And for Power over Ethernet applications, the cable might need specific testing per UL 2043 for plenum spaces or evaluation against ampacity tables in NEC Section 725.144.

When quoting cable for complex projects, the key is identifying every applicable requirement and confirming the proposed cable satisfies all of them. Missing a single required certification can delay the project while replacement product is sourced. Worse, discovering after installation that cable doesn't meet requirements can mean costly removal and reinstallation with compliant product.

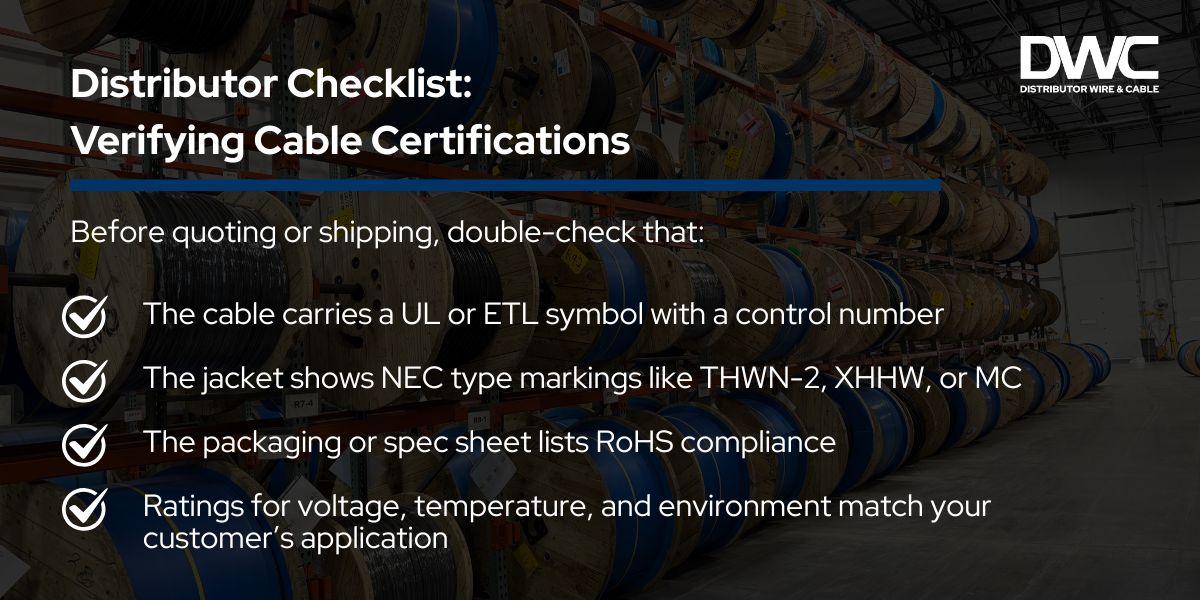

Verifying Certifications Are Legitimate

The unfortunate reality is that counterfeit or mismarked cable exists in the market. A cable jacket might display UL or ETL marks without ever undergoing actual testing and certification. Or the cable might have legitimate certification under one standard but carry marks for certifications it doesn't actually possess. For distributors, verifying that certifications are legitimate protects your business and your customers.

Legitimate certified cable has specific marking requirements. UL Listed cable must show the UL symbol, the product identity (like "Type THHN" or "Type NM-B"), manufacturer identification, applicable standards, and ratings like voltage and temperature. The markings must appear at regular intervals along the cable length—typically every 24 inches for building wire. Cable lacking these complete markings should raise immediate suspicion.

Beyond the cable jacket itself, legitimate certified cable comes with documentation. Manufacturers provide spec sheets listing all certifications, test reports showing results of flame testing and other evaluations, and declarations of conformity for requirements like RoHS. Distributors should maintain this documentation, and contractors may need it for final inspection or warranty purposes.

For verification beyond the cable markings and manufacturer documentation, UL maintains an online database called UL Product iQ where you can search for certified products. Enter the manufacturer name and product type, and the database will show all UL listings for that manufacturer, including the specific test standards the product meets and any limitations on its use. ETL maintains a similar directory of certified products. If a cable claims ETL certification but doesn't appear in the ETL directory, something is wrong.

The consequences of installing counterfeit or incorrectly certified cable go beyond failing inspection. Insurance companies can deny claims if fire or electrical failure involves cable lacking proper certification. Liability falls on whoever installed the uncertified product. And for the distributor who supplied that cable, the reputation damage can be severe when a customer discovers they were sold noncompliant product.

Red flags to watch for include prices significantly below market norms, unfamiliar manufacturer names, inconsistent or incomplete markings, documentation that seems generic rather than product-specific, and resistance from suppliers to providing detailed certification information. When something seems off, take the time to verify certifications through official channels before accepting or reselling the product.

When You Don't Need Certifications (And When You Do)

Not every application requires certified cable. Understanding when certifications are mandatory versus optional helps avoid over-specifying product and adding unnecessary cost to projects.

Certified cable is legally required for permanent building installations covered by the NEC. If the cable runs through walls, ceilings, raceways, or cable trays as part of a building's permanent electrical system, it needs appropriate certification. This includes residential, commercial, and industrial buildings—essentially anywhere the NEC applies and electrical inspectors have authority.

Certified cable is required whenever fire safety is a concern. Plenum installations need CMP rated cable. Riser installations between floors require CMR. Even general building wiring uses cable that passed flame testing. These aren't recommendations—they're code requirements that inspectors will enforce.

Certified cable is required for installations covered by specific NFPA standards beyond NFPA 70. Fire alarm systems need FPLP or FPLR cable. Healthcare facilities may require cable meeting NFPA 99. Industrial machine tools reference NFPA 79. Emergency power systems must satisfy NFPA 110. Each of these standards mandates certified cable appropriate to the application.

However, some applications fall outside these requirements. Temporary power for construction sites, especially when cables won't be concealed, may use portable cord types that carry less stringent certification. Low-voltage systems below 50 volts operating in non-fire-rated spaces might use cable without full NEC certification. Factory floor robotics using flexible cable in exposed, supervised industrial environments can use specialty cable meeting equipment manufacturer specifications rather than building code requirements.

The key is understanding jurisdiction and inspection requirements. When in doubt, assume certified cable is required. The marginal cost difference between certified and uncertified cable is trivial compared to the cost of tearing out an installation that fails inspection. And the liability protection that legitimate certification provides is worth far more than any savings from using uncertified product.

Selecting the Right Certifications for Your Application

With the landscape of cable certifications established, the practical question becomes: what certifications do I need for this specific project? Walking through the decision process systematically ensures nothing gets missed.

Start with the installation method. Is this cable going in conduit, in cable tray, direct burial, aerial, inside equipment, or exposed? Each installation method has different NEC requirements, and the cable must be suitable for that method. Type THHN works great in conduit but cannot be direct buried. Type USE can go underground but doesn't work for interior wiring. Type TC runs in cable tray but isn't suitable for conduit installation.

Consider the environment. Interior dry location versus exterior wet exposure. Ambient temperature range—some environments exceed standard 90°C ratings. Chemical exposure from oils, solvents, or corrosive atmospheres. UV exposure for outdoor installations. Physical abuse potential in high-traffic areas. Each environmental factor might require specific jacket compounds, insulation types, or armor protection that must be certified for those conditions.

Determine fire protection requirements. Building codes classify spaces based on fire risk. Plenum spaces—those used for air circulation—require CMP rated cable. Vertical runs between floors need CMR riser cable. General interior spaces can use CMG or CMX cable depending on application. Each rating corresponds to specific flame testing and smoke generation limits.

Check for special application requirements. Fire alarm systems need FPLP or FPLR. Healthcare facilities reference NFPA 99. Industrial control requires Type TC cable meeting article 336. High-temperature environments might need specialty insulation like silicone rubber. Flexible applications could require specific portable cord types.

Verify jurisdiction-specific needs. Is this a U.S. project requiring UL or ETL listing? Canadian project needing CSA certification? European installation requiring CE mark and RoHS compliance? Some international projects might need multiple certifications from different regulatory bodies.

Document everything. The cable jacket markings, manufacturer spec sheets, test reports, compliance declarations—all of this documentation may be needed during inspection, for warranty purposes, or if questions arise later. When sourcing through a master distributor, verify they can provide complete documentation for all claimed certifications.

The reality is that many cables carry certifications beyond minimum requirements. A Type THHN wire might be listed for both dry and wet locations (THHN/THWN-2), even if only dry location approval is needed. Tray cable might carry both UL and CSA certification even if only one is required. This over-certification provides flexibility and future-proofs the installation if building use changes.

What Happens When You Get Certifications Wrong

Understanding the consequences of incorrect certification helps drive home why this matters. The costs aren't just theoretical—they show up in real projects with real money at stake.

Failed inspection is the most immediate consequence. Electrical inspectors check certification marks on cable during rough-in inspections. If the cable doesn't carry required certifications for its installation method and environment, the inspector red-tags the work. The project stops until compliant cable is installed. For the contractor, this means labor costs for removal, disposal, and reinstallation, plus the cost of replacement cable. For the schedule, it means delays while proper cable is sourced and installed. For the distributor who supplied incorrect cable, it means angry customers and potential liability for project delays.

Insurance complications create longer-term problems. After electrical failure or fire, insurance adjusters investigate whether all components were properly certified. Uncertified cable discovered during these investigations can provide grounds for denying coverage. The property owner, contractor, and potentially the distributor could all face liability for damages that insurance won't cover. Even if the uncertified cable didn't cause the failure, its presence creates complications with the claim.

Why This Matters

As a distributor, you are the link between manufacturers and the field. Supplying certified cable protects customers from costly risks and safeguards your business.

Compliance: Inspectors look for certification marks on materials used in the field. Supplying certified cable helps your customers pass inspection and keeps your inventory aligned with current code standards.

Risk management: Stocking certified products supports your customers’ compliance requirements and protects your business from liability tied to unverified materials.

Reputation: Certified cable reduces product issues, returns, and warranty claims—reinforcing your reliability as a trusted supplier.

Efficiency: When your inventory meets key certifications, you eliminate second-guessing at the counter and streamline quoting, sourcing, and customer support.

Liability exposure extends beyond immediate project costs. If electrical failure causes injury or property damage, attorneys will examine whether all components met applicable standards. Uncertified cable becomes exhibit A in negligence claims. The contractor who installed it, the distributor who supplied it, and potentially the manufacturer face lawsuits. Professional licenses can be suspended. Businesses face financial ruin. These aren't abstract possibilities—they're documented outcomes when uncertified products contribute to failures.

Reputation damage might be the highest long-term cost. Distributors build reputations on reliability and knowledge. Supply one batch of improperly certified cable, and customers question everything else you sell. General contractors remove you from their approved vendor lists. Electrical contractors find new suppliers they can trust. Rebuilding that trust takes years, if it's even possible.

The worst part about certification failures is they're entirely preventable. The incremental cost difference between certified and uncertified cable is minimal—usually a few percent at most. The knowledge required to specify correctly exists and is freely available. Yet shortcuts still get taken, through ignorance, penny-pinching, or outright fraud. None of these justify the consequences.

Your Certification Resource

Cable certifications aren't academic exercises in standards compliance. They're the difference between projects that pass inspection and projects that get red-tagged. Between installations that perform reliably for decades and those that fail prematurely. Between businesses that build reputations on quality and those that face liability and reputation damage.

At Distributor Wire & Cable, we maintain comprehensive certification documentation for every product we stock. When you need to verify that cable meets NEC requirements for Type TC tray cable, we have the UL listing documents. When a customer asks whether our building wire is RoHS compliant, we can provide the declarations and test results. When an inspector questions whether cable is properly certified for plenum installation, we have the NFPA 262 test reports.

This isn't just documentation for documentation's sake. It's protection for everyone in the supply chain. The contractor knows they're installing cable that will pass inspection. The property owner knows their building electrical system meets code. The distributor knows they're supplying compliant product backed by legitimate certification. And when questions arise—during inspection, after installation, or years later—the documentation exists to answer them.

Need to verify certifications for an upcoming project? Our technical team can walk you through the specific requirements for your application and confirm our cable carries every needed certification. Use FastQuote to quickly find certified cable with complete documentation, or contact us directly at DistributorWire.com to discuss certification requirements for complex installations.

Because in specialty wire and cable, compliance isn't optional. The certifications on that cable jacket represent testing, documentation, and ongoing quality assurance that protects everyone who touches the product. Getting certifications right isn't just good practice—it's the baseline requirement for professional electrical work. And that's what we're here to help you deliver.

The DWC Difference

Every cable you source from DWC meets or exceeds the specified standards you require. That means fewer inspection delays, fewer callbacks, and more trust from your customers. With spec sheets at your fingertips and responsive support from our team, you can move fast and stay compliant.

Have a question about certification requirements or need help matching specs to a customer’s application? Connect with your DWC Account Manager today.